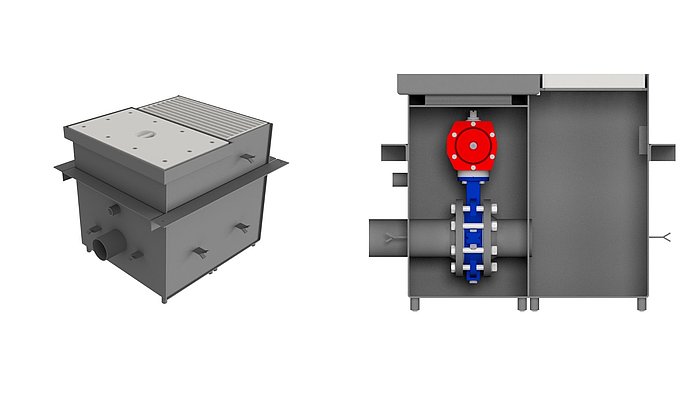

Bottom-inlet box

Bottom-inlet box

A Bottom-inlet box is an essential element in drainage technology, specially designed to ensure rainwater drainage at filling stations and track unloading points. These technical components play a central role in the effective separation of rainwater and leaking liquids, making a significant contribution to environmental safety and operational efficiency.

Function and importance of Bottom-inlet boxex

Bottom-inlet boxex are valves that are used in drainage systems to regulate the flow of rainwater. Their main function is to allow the discharge of clean rainwater while preventing contaminated liquids, such as leaks of oil or chemicals, from entering the public sewer system. This separation is particularly important at filling stations and rail unloading points, where large quantities of liquids are regularly handled.

Use of floor drain valves in track unloading

There is an increased risk of liquid leaks in track unloading areas. The installation of floor drain valves in the collection area of these areas is therefore essential. By integrating them into the drainage system, rainwater can be drained away in a controlled manner, while leakage liquids are collected in separate containers and disposed of safely. This prevents pollution of the soil and groundwater and at the same time meets the legal requirements for environmental protection.

Installation at truck loading points

Floor drainage gates are also used at truck loading points. Here, they ensure that rainwater that falls onto the loading points is drained away efficiently, while potentially hazardous liquids that could escape during loading or unloading do not enter the wastewater system. This not only protects the environment, but also contributes to the safety of operations.

Advantages and benefits of floor gully valves

- Environmental protection: The effective separation of rainwater and leaking liquids prevents water and soil pollution.

- Legal compliance: The use of floor gully valves helps companies to comply with legal environmental requirements.

- Operational safety: The safe drainage of rainwater and the controlled management of leaking liquids reduce the risk of operational disruptions and accidents.

- Efficiency: The installation of these systems enables smooth drainage at filling stations and loading points, which increases the efficiency of operational processes.