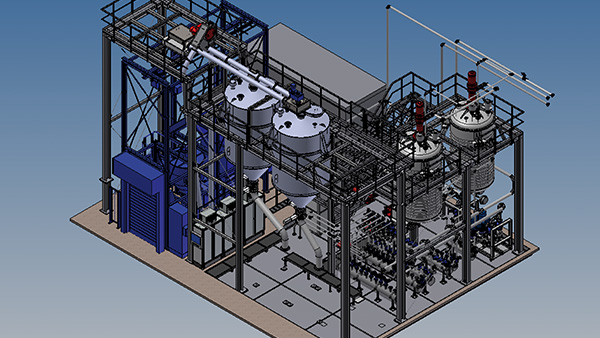

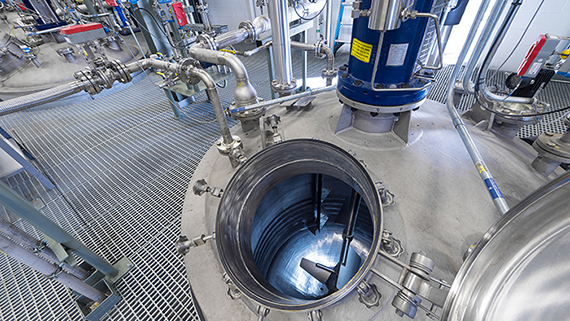

PURPLAN deliveres the whole plant construction out of one hand. To keep production downtimes to a minimum and to commission the equipment as fast as possible, a high degree of prefabrication is necessary. Therefore, all departments work close together. Starting with a feasibility analysis followed by CAD-Design, the result will be a highly-detailed bill of material. Depending on the project's scope, we distinguish between Basic Engineering, Extended Basic Engineering and Detailed Engineering. We believe, that thought-out planning and precise design are the key for a successful technical realization.

Furthermore, PURPLAN can also lead discussions with regional authorities and government agencies regarding approvals and permits.

Basis Investigation

- Examination of site conditions and infrastructure

- Exploration of planning law

- check of environmental law aspects

Planning permission under environmental law

- Coordination talks with authorities and institutions involved

- Application conference

- Definition of the subjects of the application

- immission forecasts

- Fire protection concepts

- PAAG analyses, safety reports

- Preliminary assessments according to UVP, species protection assessments

- Support with the AZB

- Comparison with conclusions BREF

- Hazard assessments

- AwSV concepts - preparation and submission of application documents

Basic Engineering

Basic Engineering refers to the phase of conceptual design within a project. During this phase, fundamental technical concepts, designs, and analyses are conducted, and the costs and risks of plant construction are evaluated. With this technical foundation, the groundwork is laid for the next step: Detailed Engineering and project implementation. Here are some of the points that fall under Basic Engineering:

- as-built/survey/3D laser scan

- 3D layout planning/3D planning

- Process engineering design

- Terrestrial 3D laser scanning (Faro 70S)

- R+I flow diagrams (Autocad PID)

- Operation and process description

- HAZOP studies/CFD study/risk analysis

- Ex-protection plans

- Alarm and hazard plans

- Circuit diagram creation (EPLAN P8)

- Authority engineering

- Sound prognoses

- Odor forecasts

- Immission forecasts

- Pipe route planning/pipeline study

- Route occupancy studies

- Support concepts

- Steel construction concepts

- Mass extracts of pipelines and steel construction

- Investment planning/budget/costing

- Time scheduling

- Room programs

- Design planning of structures and outdoor facilities, TGA

- Project scheduling

- Fire protection concepts

- Structural planning

- Construction sequence planning in coordination with production and external trades (structural and civil engineering)

- SIL considerations

- Automation concepts

- Applications according to BimschG

- AwSV concepts

- Approval plans, site plans

- Building applications and construction planning

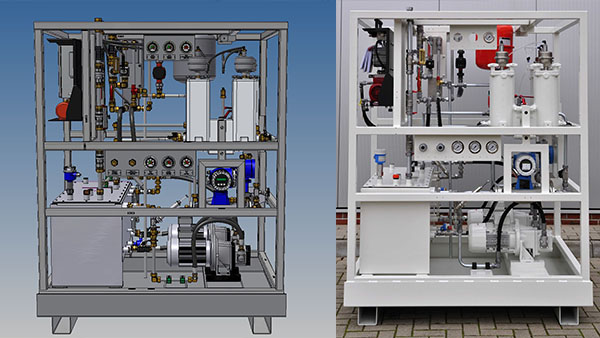

Detail Engineering

Detail Engineering refers to the final phase in an engineering project, where detailed technical elaborations and designs are carried out to prepare the project for implementation. Detail Engineering builds upon the results of Basic Engineering. Here are some of the key points addressed in Detail Engineering:

- Detailed planning with CAD/3D visualization

- 3D piping and steel construction planning

- Detail design of special solutions (Inventor)

- Pipe statics (Pipe 2)

- Static and dynamic structural analysis of piping systems

- Static proofs steel construction

- Structural analysis of piping systems

- Stress calculations/pressure surge calculations

- Design of equipment, pipe classes and components

- Specification of essential quality requirements of main components and fittings

- Preparation or detailing of tender documents

- Flange verification

- Production documents

- Operating manuals

FAQ

Engineering generally refers to the field of engineering sciences. Engineers are responsible for the planning, development, and commissioning of technologies and construction projects, including in plant construction at PURPLAN.

Basic Engineering represents the initial phase of project planning in plant construction. During this phase, fundamental technical concepts and initial designs are developed, data is collected, and the costs and feasibility of the project are assessed.

In Basic Engineering, tasks such as data collection and analysis, development of concepts and designs, calculations and simulations, cost and risk assessment, determination of requirements, and material selection are conducted. It serves as the foundation for Detailed Engineering and the subsequent phases of the project.

Basic Engineering is the initial phase of an engineering project where fundamental technical concepts, designs, and analyses are conducted to assess the feasibility and viability of the project. Detail Engineering builds upon Basic Engineering and involves the detailed elaboration, planning, and construction of the technical components and systems for the project's implementation.

Detail Engineering is the advanced phase in an engineering project, focusing on detailed technical elaborations and designs. Through precise planning, it optimally prepares for the subsequent implementation of plant construction.

In Detail Engineering, tasks such as detailed planning with CAD/3D visualization, 3D piping and structural planning, detailed design of custom solutions, static and dynamic structural analysis, flange calculations, stress calculations, equipment and component sizing, preparation of tender documents, production documents, and operation manuals are carried out.