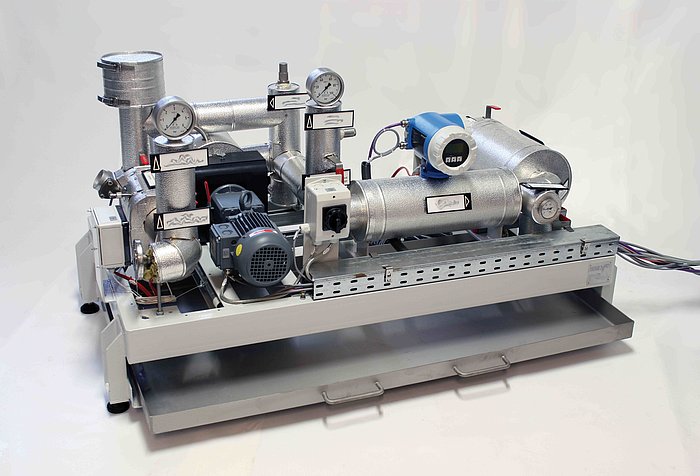

Dosing units / dosing system

Dosing units (dosing system)

Dosing systems are crucial for the precise dosing and provision of specified quantities of liquids, gases and solids. They allow processes to be easily reproducible, which is essential to meet strict quality standards while increasing efficiency through constant dosing.

How a dosing system works

The main task of a dosing system is to accurately dose a specific amount of a material, be it liquid, powder or granulate. This is usually done through an automated process that involves several components:

- Storage tanks or containers: this is where the material to be dosed is stored.

- Pumps and conveyors: These move the material from the storage tanks to the dosing point.

- Measuring equipment: These monitor the amount of material and ensure that the exact amount is dispensed.

- Control units: These computerized systems monitor and control the entire dosing process to ensure maximum precision and efficiency.

Areas of application for dosing systems

A dosing system is used to measure, dose and supply a precisely predefined quantity of liquids, gases or solids. They are used in a variety of industrial applications, including

- Food industry: here, dosing systems are used to accurately dose and mix ingredients such as flavors, preservatives or colorants, which ensures the quality and consistency of the products.

- Chemical industry: In the production of chemicals, the precise dosing of reagents and solvents is crucial in order to achieve the desired chemical reactions and ensure product quality.

- Environmental technology: Dosing systems are used in water treatment to precisely dose chemicals that are required to purify and treat water.

- Pharmaceuticals: Dosing systems are indispensable in pharmaceutical production in order to precisely dose active ingredients and ensure the consistent quality of medicines.

Advantages of dosing systems

Dosing systems offer a number of advantages that make them an indispensable part of modern production processes:

- Precision: they ensure accurate and consistent dosing, which improves the quality of the end products. Dosing precision is particularly important in the pharmaceutical and food industries, where variations in composition can have serious consequences.

- Efficiency: By minimizing human error and optimizing material consumption, dosing systems increase the efficiency of production processes. This not only leads to cost savings, but also to a reduction in waste and improved sustainability.#

- Safety: Dispensing systems enable the safe handling of hazardous or toxic materials by minimizing direct contact with operators. This reduces the risk of accidents and damage to health.

- Reproducibility: Processes that use dispensing equipment are easily reproducible, which is important to meet stringent quality standards. The ability to repeat processes accurately is particularly crucial in regulated industries such as pharmaceuticals and food production.

- Dosing unit

- dosing-units

- Dosing

Synonyme für Dosing units / dosing system