Deadman switch

Deadman switch

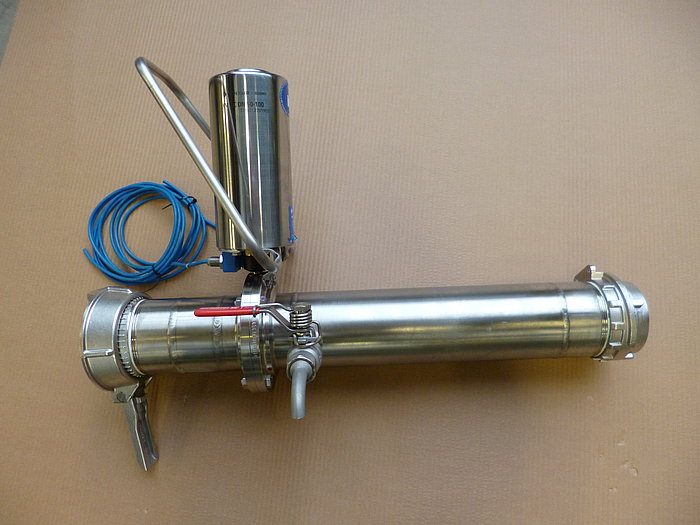

Deadman switch or ANA protection. The abbreviation ANA stands for "attention and emergency stop button" ("Aufmerksamkeits- und Not-Aus-Taste" in German) - a manually operated, automatically closing safety device that prevents the escape of large quantities of water-polluting liquids when filling containers.

Functionality and structure of the Deadman switch

This safety device consists of several components that work together to ensure maximum safety:

- Attention button: This button must be held down during the entire filling process. If the operator releases the button, the filling process is automatically interrupted. This ensures that the operator is constantly alert and can react immediately to unexpected events.

- Emergency stop button: This button allows the filling process to be interrupted immediately in an emergency. Unlike the attention button, which must be pressed continuously, the emergency stop button can be activated by a single press to immediately defuse a critical condition.

- Automatically closing mechanism: As soon as the attention button is released or the emergency stop button is pressed, a mechanism automatically closes the supply valves, preventing the liquid from leaking.

Areas of application and advantages of the Deadman switch

The Deadman switch is used in various branches of industry, especially where water-polluting liquids are handled. Typical areas of application are

- Chemical industry: Large quantities of hazardous chemicals are handled here and the risk of leaks is high. The ANA safety device helps to prevent accidents and environmental pollution.

- Petroleum industry: When filling tanks with petroleum products, overfilling can easily occur, which can lead to considerable environmental damage. The ANA safety device minimizes this risk.

- Pharmaceutical industry: This industry often uses highly potent liquids, where even small amounts that escape can cause major damage.

The advantages of the Deadman switch are manifold:

The advantages of the Deadman switch are manifold. Continuous attention monitoring significantly reduces the risk of human error, reduces the likelihood of accidents and increases occupational safety. At the same time, the automatic closing function helps to effectively prevent leaks and the spillage of hazardous liquids, ensuring the protection of soil and water and thus making an important contribution to environmental protection. Another significant advantage is the reduction in operating costs, as accidents and leaks often lead to high costs due to cleaning work and claims for damages, which can be minimized by using this safety device. In addition, the Deadman switch supports compliance with legal regulations, as many countries have strict regulations on the handling of water-polluting substances and the use of this safety device helps to comply with these regulations and avoid legal consequences.

Technical requirements and standards

The design and operation of the Deadman switch is subject to strict technical requirements and standards to ensure its effectiveness and reliability. Some of the relevant standards and directives include

- DIN EN ISO 13849-1: This standard describes the safety-related requirements for the design and use of control systems.

- VDI guideline 2263: This guideline deals with the safety requirements for handling water-polluting liquids.

FAQ

What does the abbreviation ANA mean?

The german abbreviation ANA stands for “attention and emergency stop button” - a manually operated, automatically closing safety device that prevents large quantities of water-polluting liquids from escaping when filling containers.

How does the deadman witch work?

The deadman switch works together with several components to ensure maximum safety:

- Attention button: this button must be held down during the entire filling process. If the operator releases the button, the process is automatically interrupted.

- Emergency stop button: In an emergency, this button can be pressed once to stop the filling process immediately.

- Automatically closing mechanism: As soon as the attention button is released or the emergency stop button is pressed, the supply valves close automatically to prevent the liquid from leaking.

In which industries is the deadman switch used?

The deadman switch is used in particular in industries in which water-polluting liquids are handled:

- Chemical industry: Prevents accidents and environmental pollution when handling hazardous chemicals.

- Petroleum industry: Minimizes the risk of overfilling and environmental damage when filling tanks with petroleum products.

- Pharmaceutical industry: Protects against damage caused by leaking highly potent liquids.

What are the advantages of the deadman switch?

The deadman swich fulfills the legal regulations for handling water-polluting substances. Attention monitoring reduces the likelihood of accidents and the automatic closing function effectively prevents leaks and spills of hazardous liquids. Another advantage is the protection of soil and water from hazardous liquids.

What technical requirements and standards apply to the deadman switch?

The design and operation of the deadman switch must meet strict technical requirements and standards:

- DIN EN ISO 13849-1: Safety requirements for the design and use of control systems.

- VDI Guideline 2263: Safety requirements for handling water-polluting liquids.

- ANA Protection

- deadman switch

Synonyme für Deadman switch