Polyurethan Recycling

Polyurethanes surround everyone: whether in their own homes, in their cars, at work or during leisure activities. Their supposed "invisibility" is one of the secrets of polyurethanes' success. Their existence is often only noticed when they are missing. Polyurethanes can be found, for example, in building insulation, mattresses, car parts, furniture upholstery, refrigerator and freezer insulation, adhesives, paints and shoe soles. This list is long and shows the wide range of applications for polyurethanes. At the same time this material can take very different forms and strengths.

Polyurethanes have a long life due to their structure. If products with polyurethanes need to be replaced, then in most cases due to the characteristics of other product components. But polyurethanes shouldn't simply be disposed. Polyurethane recycling is resource-saving and ecological, while Mechanical PU recycling is currently predominant. In this process, the plastic waste must be sorted according to the respective PU plastic type. They are then cleaned, shredded and melted down. This produces recyclates, which can then be used to manufacture new products. The recyclates serve as substitutes for new polyurethanes.

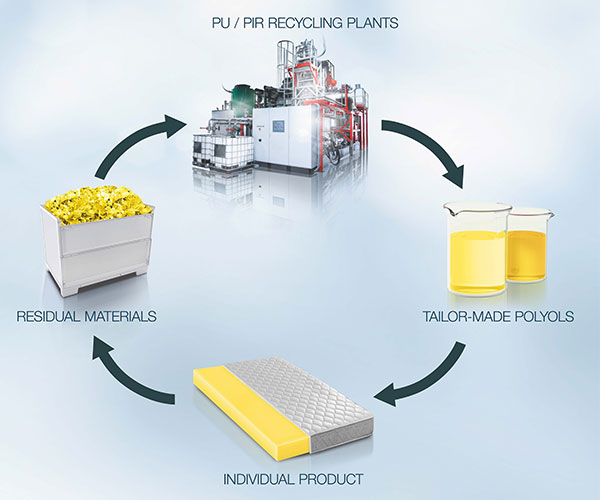

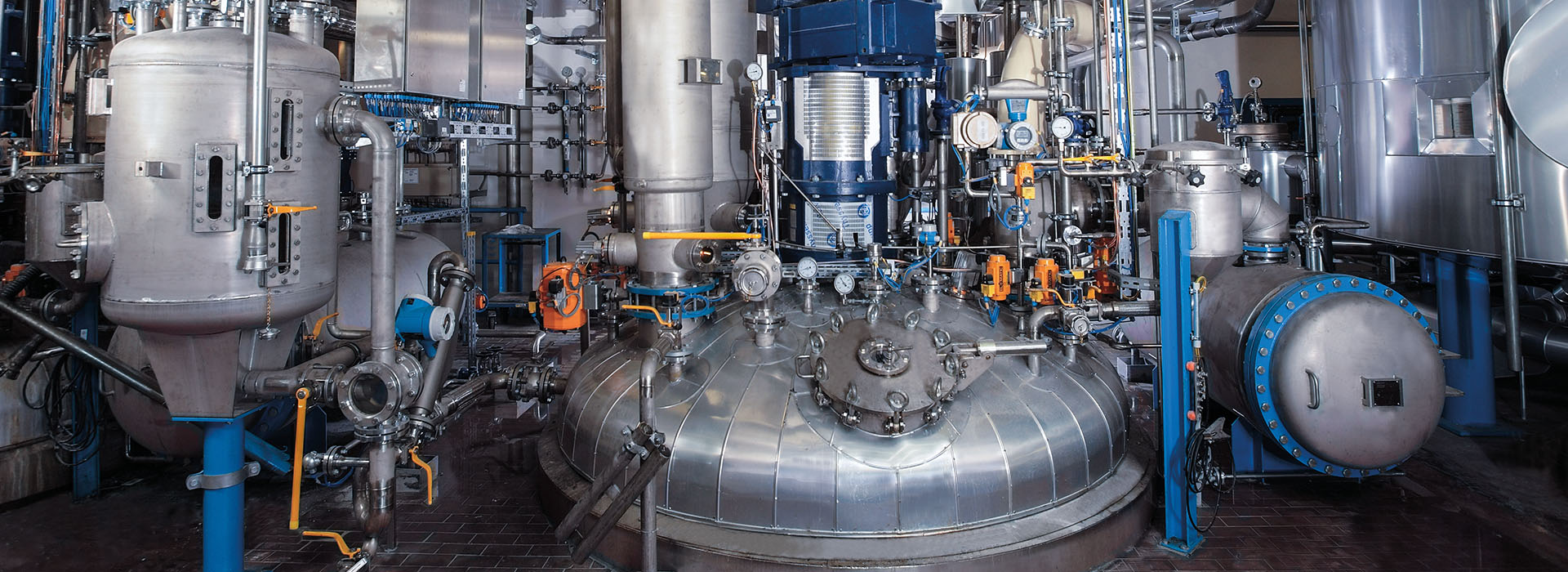

PU recycling stands for the holistic planning and assembly of process engineering systems for the production of alternative polypoles from PUR and PET residues.

In cooperation with RAMPF Eco Solutions, production residues are turned into high-quality raw materials. Our tailor-made systems reduce your raw material, transport and disposal costs and enable environmentally friendly PUR production.

PURPLAN and RAMPF combine many years of experience in the development of innovative, sustainable solutions in industrial plant construction. We guarantee your success through comprehensive support. The systems can also be used for the production of new polyols based on phthalic anhydride. Smaller amounts of waste can also be recycled economically.

The Recycling Process

There are a total of three methods for polyurethane recycling in order to utilize and, if necessary, reuse old polyurethane foam: thermal, mechanical and chemical recycling methods. Thermal polyurethane recycling is used for polyurethane foam that is not suitable for the mechanical or chemical recycling process. With thermal recycling, electricity or heat is generated through combustion.

In mechanical PU recycling, polyurethane products are crushed, granulated or ground. The use of binders or fresh polyurethane mixes these polyurentane residues. The use of heat and pressure enables a new compound to be formed. This results in new molded parts with a high recycled content.

It does not matter whether the foam is rigid or flexible. This can then be used to make various molds for new composite foam products. This recycled material serves, for example, as carpet underpadding or soundproofing applications. In this way, the polyurethanes remain in the material and economic cycle. This means that much less raw material is required. The efficiency and environmental friendliness makes PU recycling so valuable.

Alternatively, there is also chemical PU recycling with different chemical processes. These chemical processes include acidolysis, glycolysis and hydrolysis. Basically, high temperatures occur in these processes, so that polyurethane chains are converted back into raw material. The polyols obtained have the same properties and functionalities of the starting material. Therefore, they can be used to produce similar products to those recycled. Chemical recycling is associated with a high energy input compared to mechanical recycling.

Products from Polyurethanes

Polyurethane is particularly versatile in products. It is impossible to imagine modern human life without them. The flexible product characteristics, safety, recyclability and low-cost production contribute to the growing success of polyurethanes. Moreover, polyurethanes are not a scarce resource. They can be produced at any time to very specific specifications.

For example, polyurethane insulating foam is part of refrigerators and freezers. Polyurethane insulating foam makes an important contribution to energy reduction. With the use of such polyurethane foams, food is kept fresh for a long time at low temperatures. Polyurethane insulating foam in refrigerators and freezers has high rigidity and robustness. It is also lightweight, which reduces transportation costs during the cold chain. Ultimately, the low production costs also lead to low prices for refrigerators and freezers.

Polyurethanes also play a major role in building insulation. Here they make a valuable contribution to reducing CO₂ emissions and stopping climate change. Polyurethanes in building insulation are very durable, very lightweight, very safe and very cost-effective. Polyurethane insulation reduces heat loss from buildings in the cold season and helps cool them in the summer. Recyclability is another advantage of polyurethane insulation.

In addition, polyurethane foams for seating and beds are soft, dimensionally stable and lightweight. People are usually unaware that they are currently sitting or lying on polyurethane foams. This excellent comfort leads users to simply enjoy their seating furniture or mattress. This is because polyurethane foams adapt to the contours of the body in question, offering a gentle sitting or lying experience.

These different uses are indicative of the versatility of polyurethanes. Polyurethane can also be found in carpet underlays, in footwear, in textiles, in car parts, in coatings or in binders. Polyurethanes do their work almost invisibly: for the benefit of people and the environment.

Polyurethane disposal

PU recycling stands for the holistic planning and assembly of process engineering systems for the production of alternative polypoles from PUR and PET residues.

In cooperation with RAMPF Eco Solutions, production residues are turned into high-quality raw materials. Our tailor-made systems reduce your raw material, transport and disposal costs and enable environmentally friendly PUR production.

PURPLAN and RAMPF combine many years of experience in the development of innovative, sustainable solutions in industrial plant construction. We guarantee your success through comprehensive support. The systems can also be used for the production of new polyols based on phthalic anhydride. Smaller amounts of waste can also be recycled economically.

With our special approach you get your own, tailor-made and cost-efficient polyol production. At the same time, your polyols retain a particularly high quality. By reusing production residues, fewer raw materials are used and energy consumption is also significantly reduced.

With our PU recycling, the entire production cycle is more ecologically sustainable and environmentally friendly. Because if more products are made from recycled PUR in the future, fewer raw materials will flow into waste incineration for energy recovery. This also reduces CO2 emissions. In addition, less plastic waste ends up in landfills.

Rely on PU recycling now!